Why Vacuum Forming is the Ideal Choice for Spa & Hot Tub Manufacturing

Traditional spa shell manufacturing methods, such as fiberglass molding and injection molding, come with high material costs and long production cycles. Vacuum forming provides a more efficient alternative, offering:

- Seamless & Leak-Proof Designs: Eliminates seams and joints, reducing the risk of leaks and cracks.

- Exceptional Durability: Uses impact-resistant plastics that withstand high temperatures, moisture, and UV exposure.

- Lightweight Yet Sturdy Construction: Easier to transport and install, with superior strength.

- Customizable Finishes & Textures: Achieve high-end aesthetics with different colors, gloss levels, and anti-slip textures.

- Cost-Effective & Scalable Production: Reduces waste, energy consumption, and material costs, making it ideal for mass production.

Vacuum forming allows manufacturers to produce spa shells faster and with greater precision, leading to better performance, durability, and design flexibility.

Vacuum Forming Applications in the Spa & Tub Industry

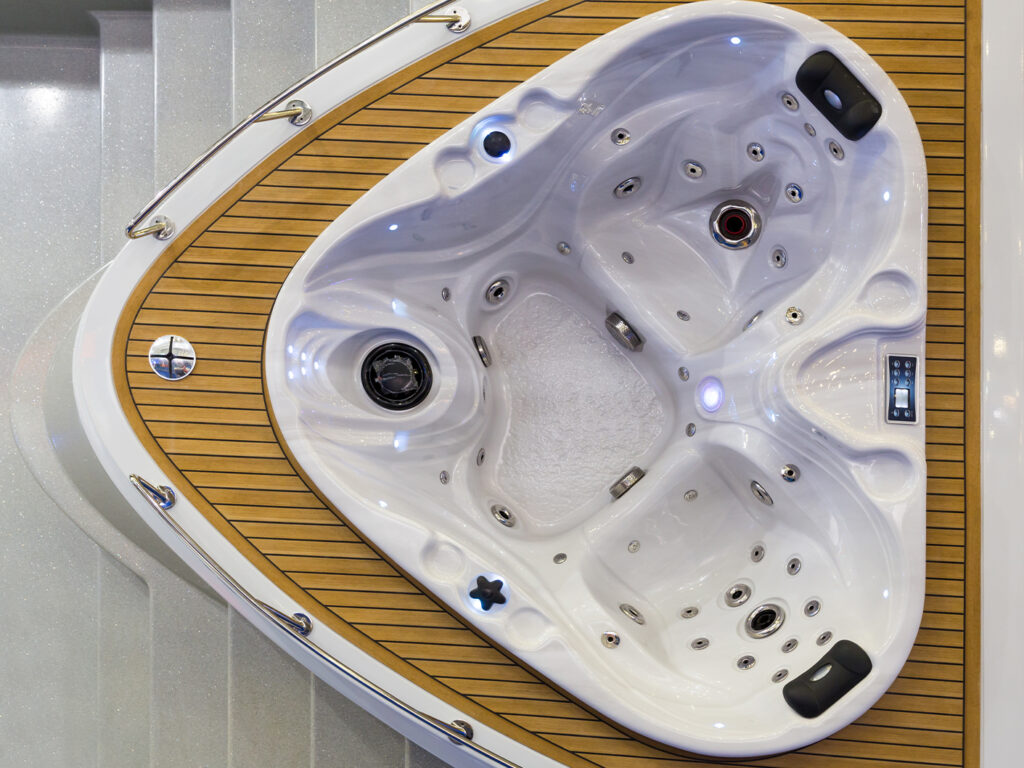

- Seamless Spa Shells & Hot Tub Liners: Smooth, impact-resistant surfaces designed for long-lasting water exposure.

- Ergonomic Seating & Lounge Areas: Contoured backrests and seating for ultimate relaxation and comfort.

- Jet Housing & Hydrotherapy Components: Custom-molded parts that enhance massage therapy functions.

- Decorative Surrounds & Panels: Durable, lightweight panels that improve insulation and aesthetics.

- Protective Covers & Thermal Shields: Energy-efficient, UV-resistant covers that enhance spa longevity.

Vacuum forming enables custom shapes, enhanced durability, and superior finishing options, making it a must-have technology for spa and hot tub manufacturers.

Belovac’s Advanced Thermoforming Solutions for Spa & Tub Production

At Belovac, we design state-of-the-art vacuum forming machines that help manufacturers streamline production while maintaining premium quality.

- Large-Format Vacuum Forming Machines: Perfect for full-size spa shells, enclosures, and protective covers.

- BV A-Class: A fully automated thermoforming system for high-volume production.

- BV C-Class: A flexible, cost-efficient machine for custom or low-batch manufacturing.

With Belovac’s precision-engineered machines, spa and tub manufacturers can achieve exceptional quality, faster production speeds, and reduced material waste.

Shaping the Future of Spa & Hot Tub Manufacturing

As demand for luxury spas and high-performance hot tubs continues to rise, manufacturers must adopt cutting-edge solutions to remain competitive.

By integrating vacuum forming technology, manufacturers can:

- Reduce production costs

- Improve design flexibility

- Enhance durability and product lifespan

- Increase energy efficiency

Partner with Belovac for Next-Level Spa Manufacturing

The future of spa and tub manufacturing is smarter, faster, and more efficient—and Belovac is leading the way. Whether you’re producing custom-designed hot tubs, hydrotherapy units, or large-scale spa enclosures, our vacuum forming solutions provide the precision and efficiency you need.

Want to take your spa and tub production to new heights?

Contact us today to learn how Belovac can help you innovate and scale your business!